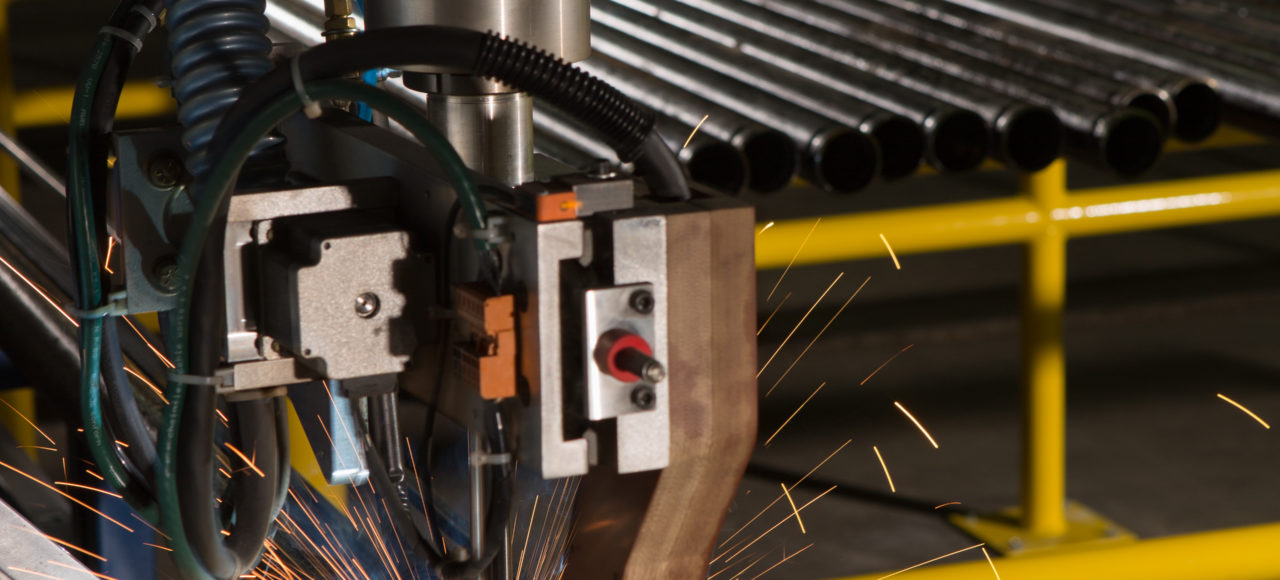

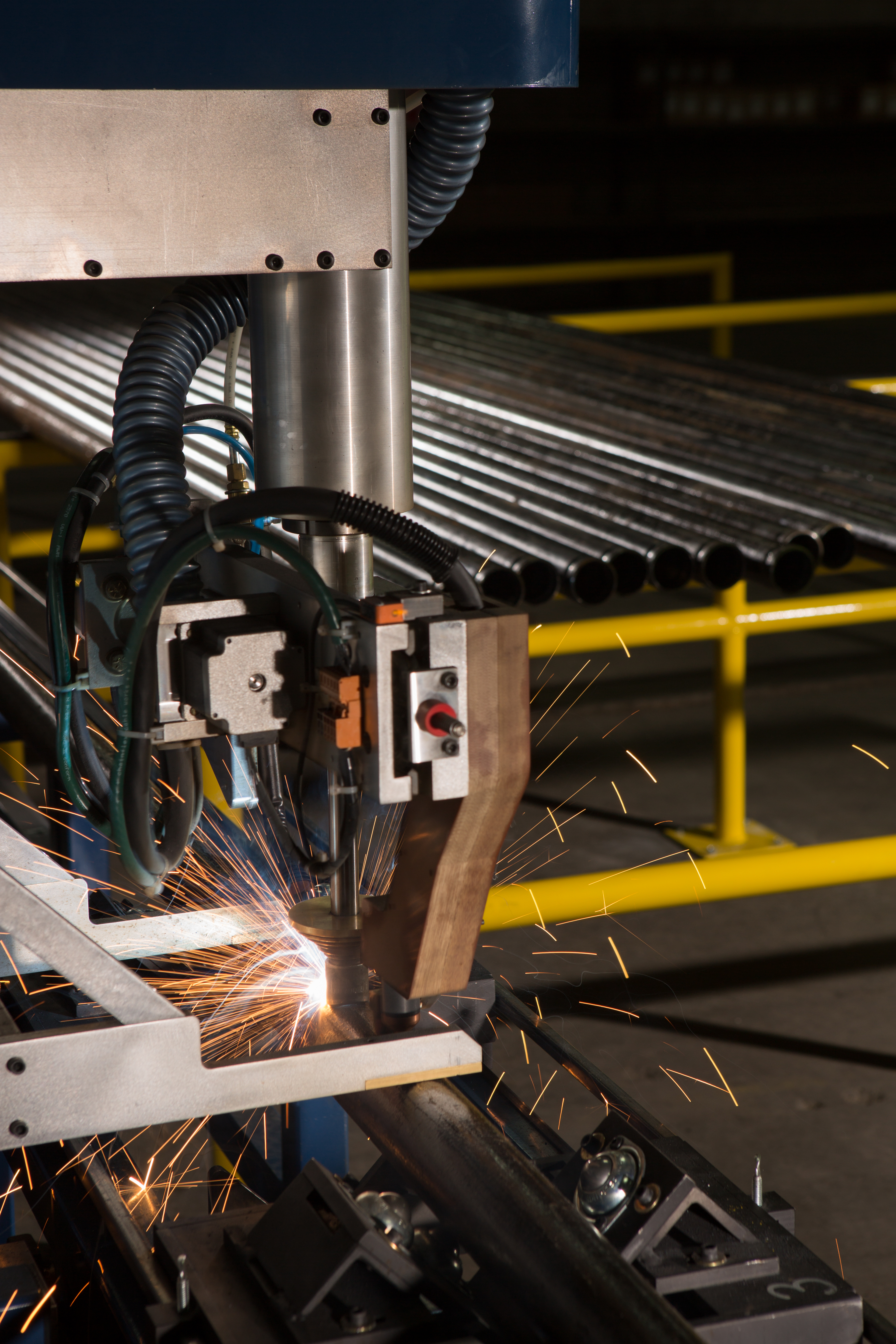

By centralizing fabrication operations for numerous decentralized projects, economies are gained for all clients through reduced man-hours, greater quality control and mechanical projects completed on time, every time.

Each plumbing/piping assembly is fabricated according to the specification requirements and then shipped to the jobsite for installation by our construction team. By fabricating all of our piping materials in-house rather than on the jobsite, we can ensure higher quality control while saving money.